Thick slices suction molding machine is the plastic sheet as raw material, through the vacuum plastic molding process for making vacuum forming plastic parts of key process equipment, it by thermoplastic plastic sheet as raw material, through the oven heated to a softening temperature, and then through the plastic sheet and vacuum forming mould between the vacuum negative pressure effect, make in the state of the thermoplastic plastic plate adsorption in the vacuum forming mold cooling molding again on the working plane.

In general, the thick plate blister machine is composed of plate positioning system, blister mold positioning system, frame system, heating system, cooling system and electrical control system.

(1) the plate positioning system is generally composed of the pressure-feed frame of the profile, the power cylinder or oil cylinder and the balance synchronization mechanism. Its function to the plastic plate plays a role in positioning. The pipe-feed frame of the straddle heating mode is upper and lower structure, and the transverse locking mechanism is added to ensure that the pipe-feed frame can be closed tightly with the plate pad. The frame can be adjusted according to the size of the mould.

(2) the positioning system of thick film blister production is generally composed of upper and lower mould table, upper and lower mould cylinder or oil cylinder and synchronous mechanism. Its function is to accelerate the positioning of the blister mold and the mold and vacuum pipeline connection. Positioning method manual screw lock or pneumatic automatic lock two ways. The synchronous mechanism can ensure up and down mould synchronously, and ensure the precision of blister forming.

(3) the frame system generally consists of profile frame, sealed box and protective door. Protective door is divided into automatic and manual parts;

(4) the heating system is generally composed of heating brick or heating tube, oven rack and power cylinder or motor;

(5) the cooling system is generally composed of gas, water pipes and spray heads;

(6) electrical system the electrical control system and the pressure or hydraulic system work together, which can realize the process requirements (temperature, speed, time) and various program actions of the blister machine. It is mainly composed of PLC, touch screen, contactor, electronic component, temperature adjusting instrument, electromagnetic valve and sensor. There are three control methods: manual, automatic and adjustment.

The principle of thick sheet suction is similar to that of thin sheet suction, which is a process of heating the positioned plate to the softening state through the oven, forming an airtight space between the mold and its surrounding, and instantly removing air from the mold cavity.

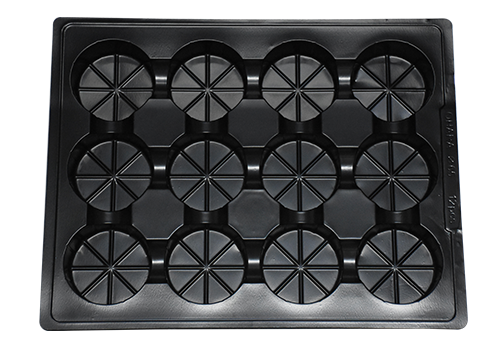

Blister molding is a cycle of the process, each cycle mainly includes: feed - heating softening - blowback pre - pull - blister - cooling molding - stripping. Remove the plastic parts and then place the sheet (received or automatic) for the next cycle.

contacts:yanmei

tel:159 0765 2175

wechat:159 0765 2175

Q Q:525377158

Email:zsshunxin@vip.126.com

web:www.zsshunxin.com