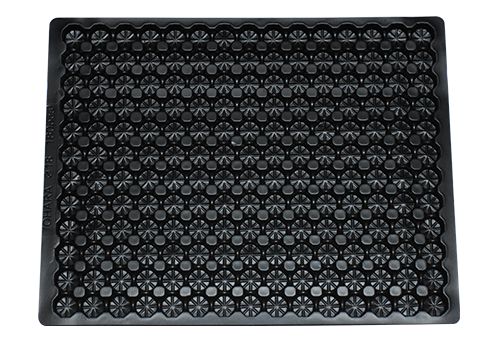

Blister molds refer to the molds used in the production of thick sheet blister. The lowest cost is gypsum mold, followed by electroplating copper mold, and the most expensive is aluminum mold. The mold is drilled with holes for vacuum adsorption of thermalized hard film to form a blister product. Blister manufacturing technology is the application of air pressure principle, the use of blister machine equipment to produce a variety of products packaging, floor tile mold and process mold practical production technology, the use of the technology is very extensive, rapid production, small investment, efficient, high efficiency.

1. A set of equipment and tools vacuum blister machine, mold, polyvinyl chloride or polyethylene plastic sheet coils (different thickness sheets are selected according to the specifications).

2. Production technology

(1) mold making and processing: According to user requirements specification or samples, first of all make good blister mold, general conditions, are made use of gypsum blister mold, but also useful wooden and metal engraving products mold, plaster mold is made, let the natural drying or drying completely, and then, on the basis of the condition of the product surface convex concave in 1-2 mm drill flower in does not affect product packaging appearance dips many drill holes, if it is products such as packaging, also have to drill some holes on the edge of the around, so that the blister production, can take out the air, the mold after drilling the well hole, also will be hardened gypsum mould processing, The method of hard treatment is soaked with concentrated alum saturated solution and then dried.

(2) after the mold is completely dried, the mold is loaded onto the iron plate of the upper part of the vacuum chamber, and then the plastic sheet is loaded into the applicable specification and size according to the mold size. Then the piece is put into the heated wooden cabinet, which is completely fixed, and then the wooden cabinet and the plastic sheet are placed on the thermostatic furnace for softening treatment.

(3) place the softened plastic sheet together with the wooden cabinet in the vacuum chamber, start the suction switch and suck the air out of the vacuum chamber. After the plastic sheet is cooled, the same concave packaging or process mold is obtained.

(4) finishing; The product that produces undertakes repairing edge is finished product namely, can sell after packing again.

contacts:yanmei

tel:159 0765 2175

wechat:159 0765 2175

Q Q:525377158

Email:zsshunxin@vip.126.com

web:www.zsshunxin.com