In our life, there is no place for thick film blister production products. The principle of thick film blister is to use vacuum blister hot press molding.

In the past 60 years, vacuum blister technology has developed rapidly, and thick sheet blister products have quickly occupied the market. In our daily life, there are various kinds of thick plate blister products.

Thick film blister products, widely used in equipment and machinery shell, household appliances, TV rear cover, electric vehicles, automotive thick film blister, and so on.

Due to the low price, high quality, short development time, cheap mold and thick film blister products gradually replaced part of injection molding products, many large brands switched to the blister processing technology of TV rear cover, household appliances shell, automobile accessories.

Thick film blister products will involve more industries in the future.

Thick plate blister is a kind of vacuum blister process formed by heating, it can use the sheet of thermoplastic material to make the thick plate blister shell of opening.

The plate used by the thick plate is cut into the required size and then heated to soften with the help of the thick plate

The pressure of the pressure difference and thick plate suction machine, which deforms and then is pasted onto the thick plate of the product specific aluminum mold

The contour surface is then cooled by the special cooling machine for thick plate suction molding machine, and the cutting edge is trimmed and processed.

Main production equipment:

Thick film blister machine, acrylic laser machine, imported CNC, plane cutting machine, cutting machine, bending machine.

Principle of blister making:

A plastic processing technology to thermoplastic plastic sheet as raw material, through the oven heated to a softening temperature, and then through the plastic sheet and vacuum forming mould between vacuum negative pressure effect, make the plastic in the mold surface adsorption, seal around the inside of the smoke vacuum, let sheet completely stick tightly on the mould, it will get to mold the shape of the same, with a fan and water cools the plank, ejection molding.

Advantages and disadvantages of thick film blister:

In the field of plastic processing, it is considered to be a processing method with great development potential. It has the advantages of low price, low cost, high production efficiency, free selection of shape and color, corrosion resistance and light weight. However, the thick blister moulding can only produce semi-shell products with simple structure, and the wall thickness of the products is not uniform (generally, the straight side is slightly thin), so it is impossible to make plastic products with the same wall thickness.

Scope of application:

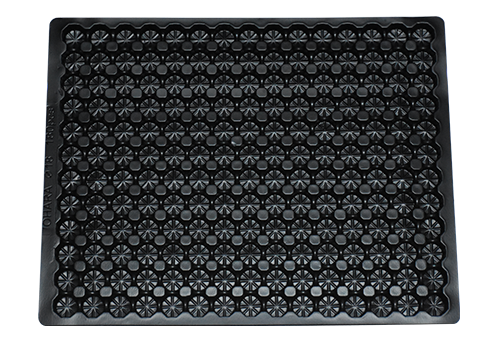

At present, it is applicable to a wide range of industries, such as machine casing, people power, electric vehicle cover, logistics tray, large toys, lighting outer cover, advertising lamp box, display rack and sanitary ware.

contacts:yanmei

tel:159 0765 2175

wechat:159 0765 2175

Q Q:525377158

Email:zsshunxin@vip.126.com

web:www.zsshunxin.com